3D laser processing – countless possibilities

At BRANTNER, made possible through the most advanced laser technology

We are happy to assist you with our expertise.

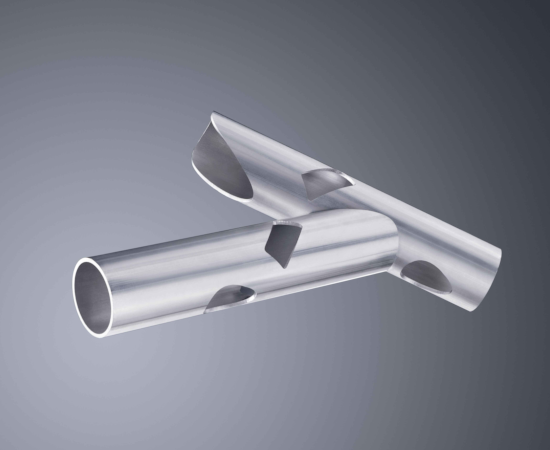

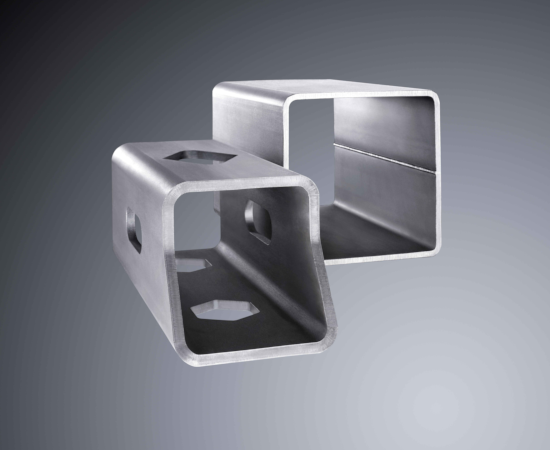

Our customers receive their parts from our tube laser processing system with high quality, flexibility, and reliability. Not only does it provide an advantage over conventional processing methods, but it also opens up new possibilities through smarter designs, making the purchase of tube laser parts a wise choice.

Reduction of cutting times

Through the full automation of the tube laser system, each part is completely cut in a single pass. It is no longer necessary to drill separate holes or perform weld seam preparation with an angle grinder afterward.

3D-tube laser Trumpf Tube 7000

TruFlow 3600W

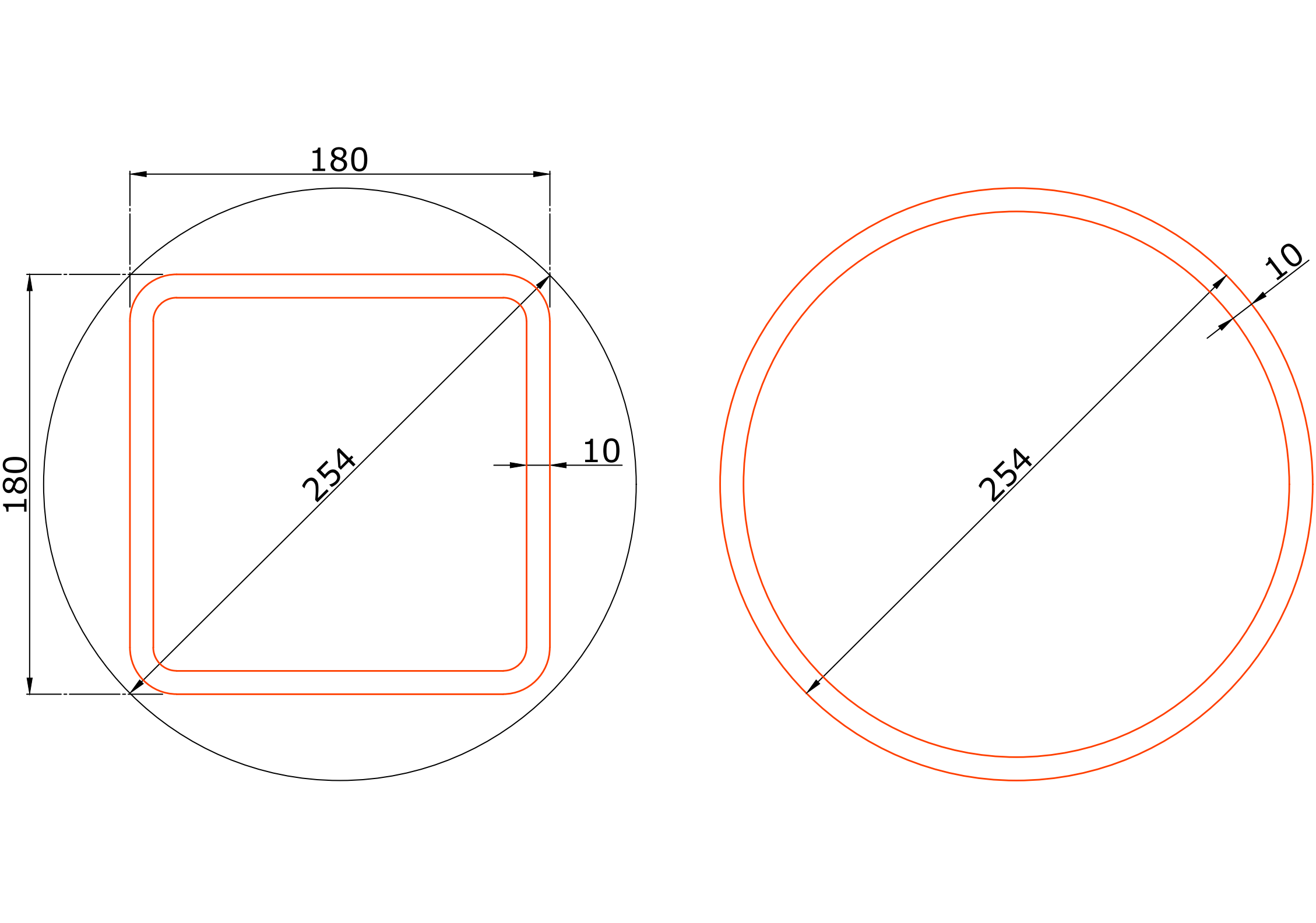

| Envelope diameter | 15 - 254 mm |

| Raw material length | 7000 mm |

| Finished part length | 6080 mm |

| Raw material weight | 38,5 kg/m |

| Material thickness (steel) | 10 mm |

| Material thickness (stainless steel) | 6 mm |

| Material thickness (aluminum) | 5 mm |

| Corresponds to: | |

| Square hollow profiles | bis 180x180 mm |

| IPE-Profile | 80 - 220 |

| HEA-Profile | 100 - 180 |

| HEB-Profile | 100 - 140 |

| U-Profile | 80 - 220 |

| L-Profile | bis 180x180 mm |

| Processable file formats | |

| Assembly models | STEP/IGES/SAT/SLDASM |

| Part file formats | DSTV/DWG/DXF/SLDPRT |

Reduction of assembly times:

Parts produced by a tube laser system can be equipped with numerous features to make these constructions smarter. Starting with positioning aids in the form of a pin-and-socket system, or with precise, tenth-of-a-millimeter accurate holes. It is also possible to create a single part instead of several individual components, which only needs to be shaped afterward.

Reduction of welding effort:

Precise cutouts and/or weld seam preparations also reduce the welding effort. Oversized gaps, which would otherwise require laborious welding, are not present in parts produced by our tube laser system.

With the help of the tube laser, profiles of all kinds can be cut. Limitations exist based on the profile dimensions, such as the envelope diameter ranging from 15 to 254 mm, the bar length of 7000 mm on the loading side, 6080 mm on the unloading side, and a weight of 38.5 kg/m.

The material thicknesses that can be cut without issue depend on the material being processed. For mild steel, material thicknesses up to 10 mm can be cut, while for stainless steel, it is 6 mm, and for aluminum, 5 mm.

Trumpf Tube 7000 - TruFlow3600

Quelle: Trumpf